Understanding ESD Fabric: The Greatest Guide

Introduction

Electrostatic discharge (ESD) is a critical concern in various industries, particularly in electronics manufacturing, where just one discharge can irreparably damage sensitive components. To combat this, ESD fabrics have already been developed to produce effective protection against static electricity. This comprehensive guide explores the intricacies of ESD fabric, its applications, benefits, additionally the technology behind it.

What exactly is ESD Fabric?

ESD fabric, short for Electrostatic Discharge fabric, is a kind of textile material made to dissipate static electricity, thereby preventing the accumulation and discharge of static energy. These fabrics can be used in environments where electrostatic discharge poses a risk, such as for instance cleanrooms, electronics manufacturing facilities, and laboratories.

How ESD Fabric Works

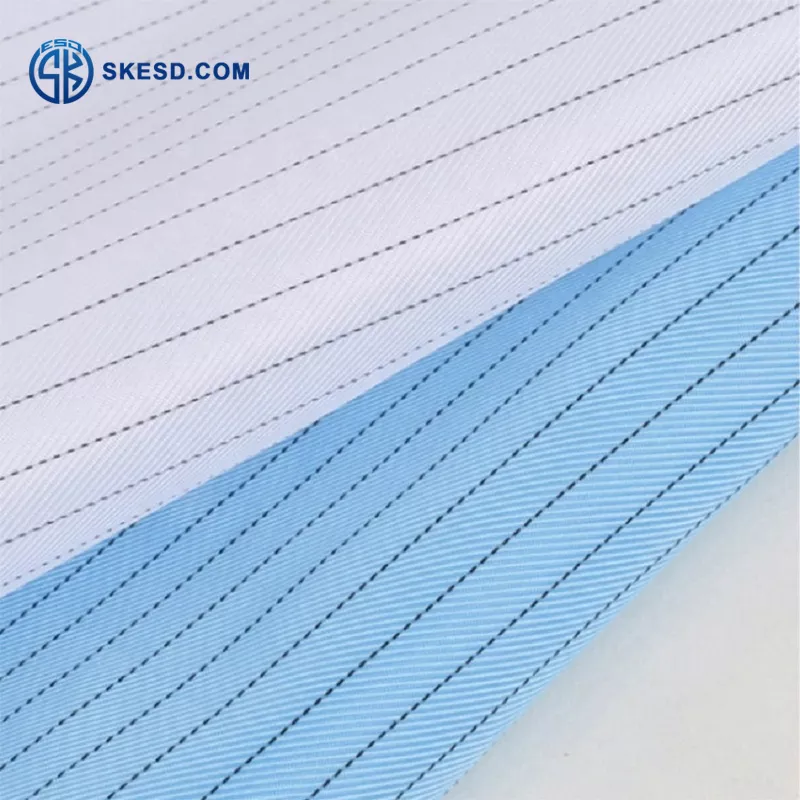

ESD fabrics work by incorporating conductive fibers in to the textile. These fibers could be made of various materials such as for instance carbon or metal-coated fibers. The conductive fibers create a grid-like pattern for the fabric, that allows static electricity to dissipate safely.

Conductive Fibers

Conductive fibers are the backbone of ESD fabric. They have been typically woven into the fabric in a grid pattern, ensuring that any static charge which comes into contact with the fabric is evenly distributed and safely discharged.

Grounding Mechanism

For ESD fabric to work, it often has to be connected to a grounding mechanism. This is done through grounding straps or by ensuring that the fabric is within experience of a grounded surface. The grounding mechanism provides a path for static electricity to safely dissipate.

Types of ESD Fabrics

There are many types of ESD fabrics, each designed for specific applications and degrees of protection.

Woven ESD Fabric

Woven ESD fabrics are created by weaving conductive fibers into the textile. This kind of fabric is durable and often found in applications where strength and longevity are necessary.

Non-Woven ESD Fabric

Non-woven ESD fabrics are produced by bonding fibers together using chemical, mechanical, or thermal processes. These fabrics are generally utilized in disposable applications, such as for instance cleanroom wipes and disposable garments.

Knitted ESD Fabric

Knitted ESD fabrics are created by knitting conductive fibers in to the textile. This type of fabric is stretchy and comfortable, rendering it well suited for garments that require flexibility.

Applications of ESD Fabric

ESD fabrics are utilized in a wide range of industries and applications to safeguard against static electricity.

Electronics Manufacturing

In electronics manufacturing, ESD fabrics are used to create protective garments, workstations, and packaging materials. These fabrics help alleviate problems with static discharge from damaging sensitive electronic components during assembly and handling.

Cleanrooms

Cleanrooms require strict control over contaminants, including static electricity. ESD fabrics are used in cleanroom garments, such as for instance coveralls, gloves, and shoe covers, to ensure that static discharge does not interfere with sensitive processes.

Medical Applications

In medical environments, ESD fabrics are acclimatized to create protective clothing and equipment. This can help prevent static discharge from affecting sensitive medical devices and ensures a safe environment both for patients and healthcare professionals.

Automotive Industry

The automotive industry uses ESD fabrics in the creation of electronic components and assemblies. These fabrics help force away static discharge during the manufacturing process and make certain the reliability of electronic systems in vehicles.

Great things about ESD Fabric

ESD fabrics offer numerous benefits in terms of safety, efficiency, and protection.

Protecting Sensitive Components

One of several primary great things about ESD fabric is being able to protect sensitive electronic components from damage due to static discharge. It will help lessen the risk of costly repairs and downtime.

Enhancing Workplace Safety

By preventing static discharge, ESD fabrics help create a safer working environment. It is particularly essential in industries where static electricity can pose a significant hazard.

Reducing Contamination

In cleanroom environments, ESD fabrics help reduce contamination by preventing particles from becoming airborne as a result of static discharge. It will help retain the integrity of sensitive processes and products.

Improving Product Quality

By protecting against static discharge, ESD fabrics help make sure the quality and reliability of electronic components and assemblies. This contributes to higher customer care and reduced warranty claims.

Selecting the Right ESD Fabric

Deciding on the best ESD fabric involves considering several factors, like the degree of protection required, the application form, as well as the environmental conditions.

Standard of Protection

Different applications require different levels of ESD protection. It is important to select a fabric that meets the precise requirements of your industry and application.

Durability and Comfort

The durability and comfort of ESD fabric are very important considerations, especially for garments which will be worn for extended periods. Woven fabrics tend to be more durable, while knitted fabrics offer greater comfort and flexibility.

Environmental Conditions

Environmentally friendly conditions where the ESD fabric should be used can impact its performance. For example, high humidity levels make a difference the potency of some forms of ESD fabrics. It is vital to choose a fabric that performs well using your specific environmental conditions.

Testing and Standards for ESD Fabric

To ensure the effectiveness of ESD fabrics, they need to undergo rigorous testing and meet specific standards.

Testing Methods

Several testing methods are widely used to measure the performance of ESD fabrics:

Surface Resistivity: Measures the resistance associated with the fabric's surface to electrical current.

Charge Decay: Assesses how quickly the fabric dissipates static charge.

Static Cling: Evaluates the fabric's tendency to cling as a result of static electricity.

Standards

ESD fabrics must conform to industry standards to make sure their effectiveness:

ANSI/ESD S20.20: Provides guidelines for developing an ESD control program.

IEC 61340: Specifies requirements for materials found in electrostatic control.

EN 1149: Defines standards for protective clothing with electrostatic properties.

Maintenance and Proper Care Of ESD Fabric

Proper maintenance and care are essential so that the longevity and effectiveness of ESD fabrics.

Washing and Cleaning

When washing ESD garments:

Use mild detergents without bleach or fabric softeners.

esd fabric at temperatures recommended by the product manufacturer.

Avoid high heat during drying as it could damage conductive fibers.

Storage

Store ESD fabrics in a clean, dry environment away from direct sunlight. Avoid folding or compressing the fabric excessively to prevent damage to conductive fibers.

Regular Testing

Regular testing of ESD fabrics is vital to make sure their continued effectiveness. Periodically test garments and materials for surface resistivity and charge decay to ensure they meet required standards.

Innovations in ESD Fabric Technology

Advancements in technology continue to improve the performance and versatility of ESD fabrics.

Nanotechnology

Nanotechnology allows when it comes to development of conductive fibers at a microscopic level. This contributes to far better dissipation of static electricity while maintaining comfort and flexibility.

Smart Textiles

Innovations in smart textiles integrate sensors and electronic components into ESD fabrics. These smart textiles can monitor environmental conditions and offer real-time feedback on static levels, enhancing safety and efficiency.

Sustainable Materials

The push for sustainability has led to the development of eco-friendly ESD fabrics produced from recycled or biodegradable materials. These sustainable options reduce environmental impact without compromising performance.

Conclusion

ESD fabrics play a crucial role in protecting sensitive components, enhancing workplace safety, reducing contamination, and improving product quality across various industries. Understanding the several types of ESD fabrics, their applications, benefits, and maintenance requirements is vital for selecting the right material to meet your needs. With ongoing innovations in technology and materials, the continuing future of ESD fabric promises even greater advancements in performance and sustainability.